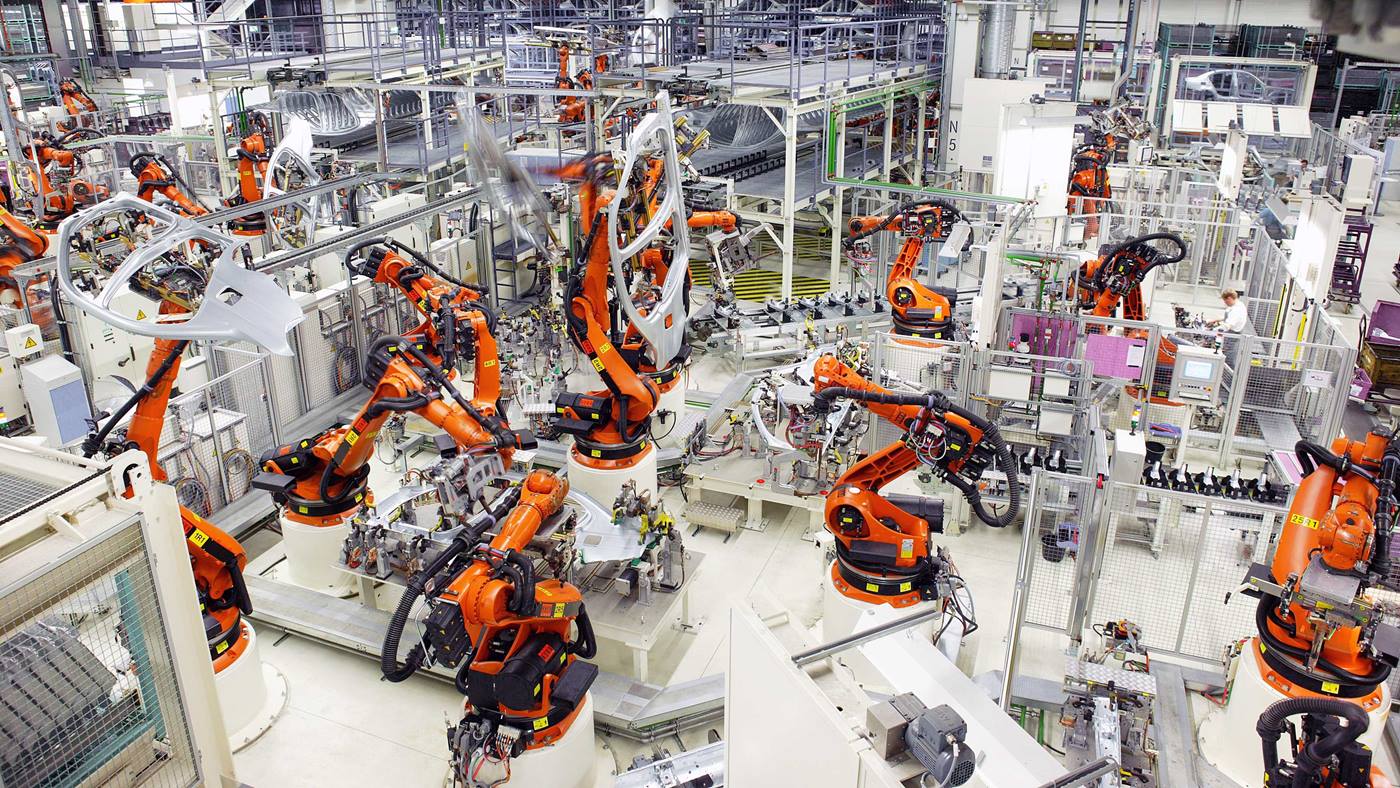

Plc programming in automotive industryAutomation is the use of control systems such as computer systems to control the industrial machinery and processes replacing human operators. An automotive engineering conference is scheduled to be held at Istanbul where future automotive trends and most current developments in automotive electronics will be discussed. The conference is becoming held for the third time and is becoming jointly organized by the Automotive Industry Association (OSD), the Vehicles Procurement Industrialists Association (TAYSAD), the Association of American Automotive Engineers (SAE) and the Automotive Technologies Platform (OTEP).

Analog signals are like volume controls, with a range of values amongst zero and full-scale. These are generally interpreted as integer values (counts) by the PLC, with various ranges of accuracy depending on the device and the number of bits obtainable to retailer the information. As PLCs usually use 16-bit signed binary processors, the integer values are limited amongst -32,768 and +32,767. Stress, temperature, flow, and weight are often represented by analog signals. Analog signals can use voltage or present with a magnitude proportional to the value of the process signal. For instance, an analog to 10 V or 4-20 mA input would be converted into an integer worth of to 32767.

Autonomous autos will revolutionize the transportation business like no other adjust because the invention of the automobile. Making these automobiles demands agile, model-based improvement with integrated data flows and a heavy reliance on computer software-based simulation capabilities. Siemens PLM Application gives a complete set of autonomous automobile options for all crucial technical domains – from chip style to full automobile validation.

Today’s Automotive Industry Featured LaggardPlc In Automotive Industry

plc application in automotive industryThis report on the global ALM market offers evaluation for the period from 2013 to 2023, wherein 2014 is the base year and the years from 2015 to 2023 are the forecast period. In the automotive industry, at present identified term Manufacturing Execution Systems (MES) in order to optimize the production method. MES combines several handle systems that offer visual management applications, immediate and paperless, one of which is the application of Supervisory Manage and Information Acquisition (SCADA) to gather genuine-time information that can successfully control and monitor industrial equipment and manufacturing processes.

Programmable controllers vary in their capabilities for a “rung” of a ladder diagram. Some only enable a single output bit. There are usually limits to the quantity of series contacts in line, and the quantity of branches that can be used. Every single element of the rung is evaluated sequentially. If components change their state during evaluation of a rung, difficult-to-diagnose faults can be generated, despite the fact that occasionally (as above) the strategy is valuable. Some implementations forced evaluation from left-to-proper as displayed and did not let reverse flow of a logic signal (in multi-branched rungs) to have an effect on the output.

What does CPM spending by manufacturing firms have to do with international marketplace competition? According to ARC, CPM is the final frontier for interfacing manufacturing, supply chain and company systems with each other to increase and track productivity, lessen waste and enhance revenues to remain competitive. In today’s competitive atmosphere CPM is the subsequent step in achieving a competitive edge in the globe industry.

What Is PLC Programming And Automation?PLC Applications In The Automotive Industry

PLC Applications In The Automotive IndustryDespite the fact that CAD is employed extensively in numerous industries, specially in the procedure of manufacturing, but nonetheless a lot of us are not aware of its wide ranging use. I feel you need to have to be much more specific. PLC’s are not employed differently no matter the application no matter whether it really is automotive or widget assembly. They all do the very same factor – replace mechanical electrical devices such as relays, timers, and counters. To be clear, there is significantly much more they can do (sequencers, PID handle, and so on), but the fundamentals remain the same regardless of how they are applied.

The emerging IT applications are altering the way enterprise is carried out nowadays. The integration of ALM is necessary in order to remove inefficiencies and blocks in the application development lifecycle approach. ALM helps a organization to develop the greatest virtual techniques for each and every phase of the software program application procedure, such as study, specifications arranging, prototyping, engineering, style, time to industry, programming, testing, risk management, defect tracking, and measurement. Benefits such as enterprise agility, enhanced organizational agility, and improved resource utilization supplied by ALM have drastically elevated the demand for this technologies worldwide. North America dominates the overall industry for ALM globally owing to surging technological advancements and automation in this area.

Machines making use of signal chains heat and cool air and water in our properties. They chill and cook our meals. In business nearly every thing that we acquire is manufactured using signal chains. Think of your automobile. (Yes, most of us jump into our automobiles without considering. We drive our automobiles to function and some individuals drive making use of the “bang-bang” method. This is not the bang-bang servo that we discuss in the Appendix, but actually hitting things.) Automotive antilock brakes, cruise controls, automatic transmissions, and traction controls are examples of signal-chain utilizes.

HomePlug Powerline AlliancePlc In Automotive Industry

plc programming in automotive industryInvestors are accustomed to tracking stock price tag volatility primarily based on familiar market place forces such as provide, demand, company management, or the cost of capital. Under the IEC 61131-3 regular, PLCs can be programmed utilizing standards-based programming languages. The most commonly utilized programming language is Ladder diagram (LD) also known as Ladder logic. It utilizes Get in touch with-Coil logic to make programs like an electrical control diagram. A graphical programming notation known as Sequential Function Charts is obtainable on particular programmable controllers. A model which emulated electromechanical handle panel devices (such as the make contact with and coils of relays) which PLCs replaced. This model remains widespread nowadays.

Though there have been several technical advancements in the pressing technology, the quantity of automation tools is restricted. A number of sophisticated technologies such as pressing robot, jacket finisher (front), shirt finisher, and shirt press have been commercially accessible. However, the labor application is nevertheless prevalent in loading or removal of the garment into the buck, smoothing, and shaping. For profitable automation of the entire garment manufacturing approach, it is crucial to obtain significant improvement in pressing in addition to the other places (cutting, sewing, and material handling).

A small various to earlier years, 3 years ago, and its computerized automobile lines of production are the simple products international sourcing, in auto production lines of China s, typically from imports, PLC concurrently with the production line introduction, only the acceptable spare parts sourcing in China. But in present years, aggressive auto market, vehicle slashed charges, organizations began to decrease costs, a lot of the automation items production line to commence of procurement. But the business of automobile is separated manufacturing industries, dissimilar components from diverse branch, use dissimilar facilities of production, a manufacturer of auto will use much more than one particular PLC brand.